Wet vs Dry Milling: Choosing the Right Method for Chairside Dentistry (3 mins read)

2025-08-12 |

Introduction

In today’s fast-paced dental practices, chairside milling is revolutionizing patient care—allowing dentists to design, mill, and place restorations in a single visit. But one critical decision shapes your workflow efficiency and clinical outcomes: Should you choose wet milling or dry milling for your chairside setup?

Understanding the differences can save you time, improve patient satisfaction, and ensure you choose the right materials for same-day dentistry.

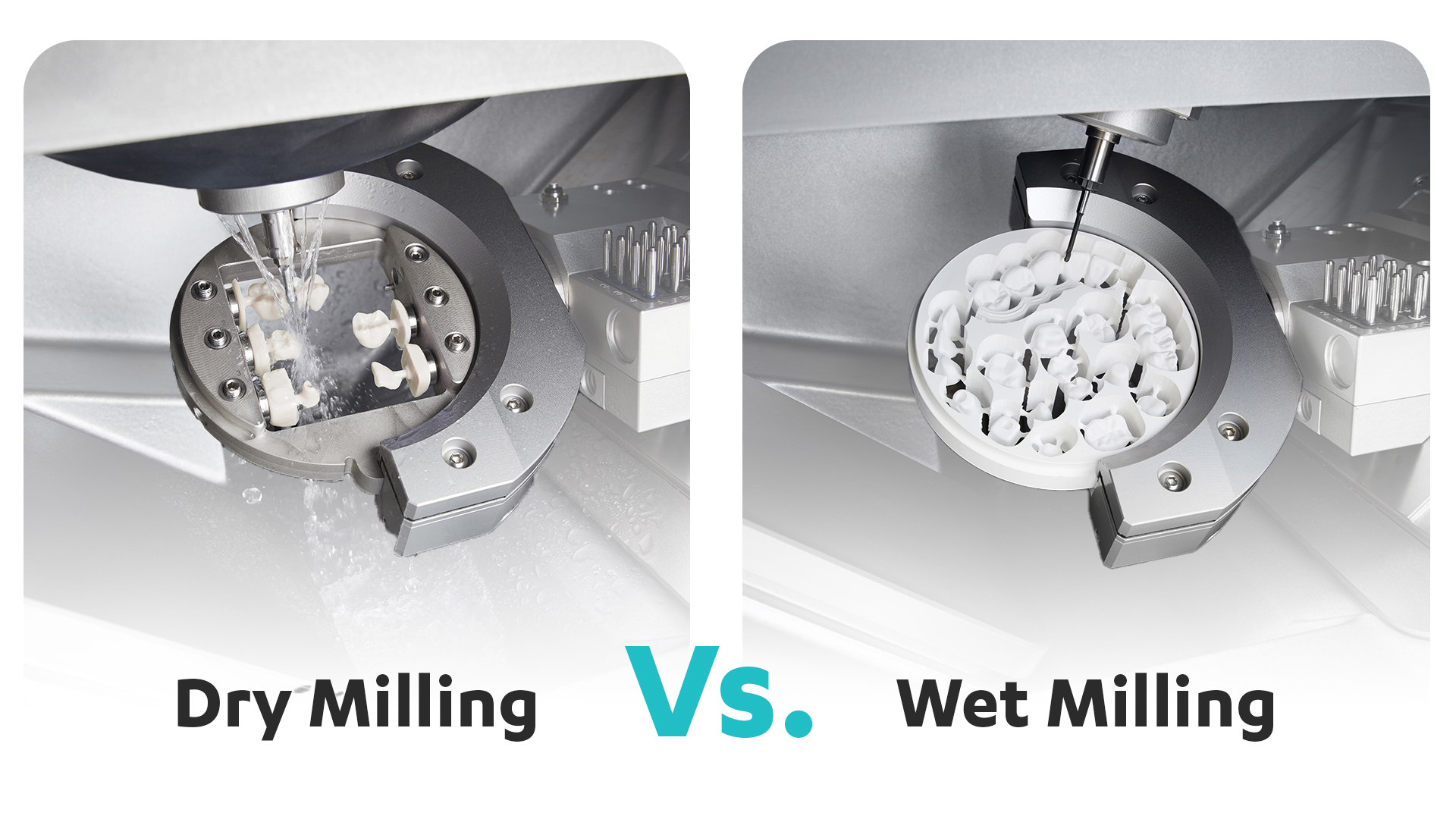

Wet Milling vs Dry Milling: The Key Differences

|

Feature |

Wet Milling |

Dry Milling |

|

Coolant Use |

Uses water-based coolant to prevent overheating |

No coolant; material milled in dry state |

|

Suitable Materials |

Glass ceramics, hybrid |

Zirconia, wax, PMMA |

|

Surface Finish |

Smooth, precise margins ready |

Requires post-processing and sintering |

|

Speed for Chairside |

Fast – can deliver restorations within hours |

Longer – zirconia requires additional sintering time |

|

Workflow |

Minimal post-milling steps |

Requires technician support and extra equipment |

Why Dry Milling and Zirconia Are Not Ideal for Chairside Workflows

While dry milling with zirconia is common in dental labs, it’s not optimized for same-day chairside dentistry. Here’s why:

- Longer Turnaround Time – After dry milling zirconia, you must sinter it in a furnace, which can take 2–8 hours depending on the furnace type. This eliminates the possibility of true same-day delivery.

- Technician Dependency – Zirconia restorations often require technician expertise for finishing, shading, and polishing.

- Equipment Investment – High-temperature sintering furnaces are costly and require space, making them impractical for smaller practices.

Why Wet Milling Wins for Chairside Dentistry

Wet milling is the preferred choice for same-day workflows because:

- No Sintering Required – Wet milling materials like hybrid ceramics and composite resins are ready for placement immediately after milling and polishing.

- High Precision & Strength – Ideal for single crowns, inlays, onlays, and veneers with precise margins and smooth surfaces.

- Patient Satisfaction – Same-day results mean no temporaries, fewer appointments, and happier patients.

Best Materials for Chairside Wet Milling

For optimal results, consider:

- Hybrid Ceramics (e.g., VITA ENAMIC®) – Excellent aesthetics, shock absorption, and quick polishing.

- Premium Crown Resin – Strong, affordable, and easy to adjust.

- Glass Ceramics – High translucency for anterior esthetics.

These materials can be milled, finished, and placed in a single visit—no lab delays.

At Alsharaa Digital Dentistry, we help clinics choose the right milling technology, materials, and workflow for maximum efficiency.

💡 Ready to upgrade your chairside milling setup?

Contact our team today for expert guidance and tailored solutions.

References:

- Zhang Y, Lawn BR. Novel Zirconia Materials in Dentistry. J Dent Res. 2018;97(2):140–147.

- Fasbinder DJ. Chairside CAD/CAM: An Overview of Restorative Material Options. Compend Contin Educ Dent. 2010;31(9):702–708.

- Spitznagel FA, et al. Chairside CAD/CAM materials. Int J Comput Dent. 2018;21(2):123–136.

Share On :

Recent Posts

- The Future Is Now: How Digital Dentistry Is Transforming Clinics in Iraq (4 min read)

-

Top Applications of Digital Dentistry

(3 min read) - Thinking About Going Digital in Your Dental Practice? (4 min read)

- How AI is Revolutionizing CAD Design for Dentists (4 min read)

- Your Lab Inside Your Clinic: The Smartest Investment You'll Ever Make (4 mins read)

- Premium Crown Resin & Hybrid Ceramic Crowns: Advancing Digital Dentistry in Iraq (4 mins read)

- Wet vs Dry Milling: Choosing the Right Method for Chairside Dentistry (3 mins read)